Self-Floating Hose

1. Design and manufacture a simulation system for fluid delivery on site, Help users to accurately understand hose life 2. Use OCRA FLEX software to help users determine hose fluid The best solution for the system 3, using 3D design software to accurately calculate product data for customers Provide reliable products that match theoretical data

Application:

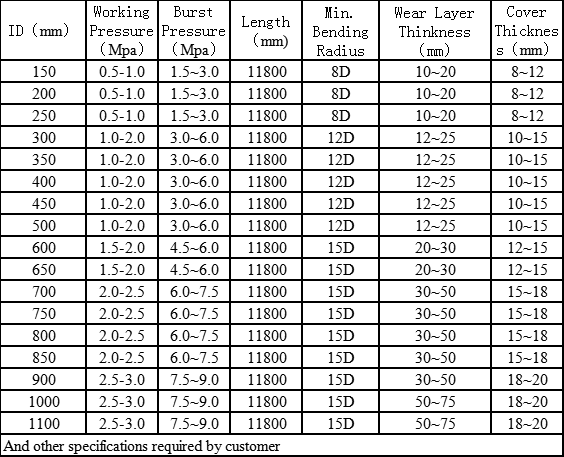

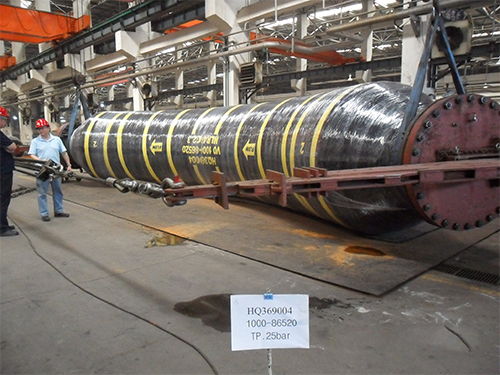

Floating hoses apply to pipelines suffer great impact of seawater surge and always being used on dredgers. The hoses with self-contained foam floats connect with each other to compose a floating pipeline. This kind of pipelines have stable floation condition, can bear powerful tension and torsion force that steel pipelines cannot sustain in extreme enviroments.

Self-floating Hose:

The inner layer of the self-floating hose is filled with low-density polymer.

It can make sure the hose emergence above water is not less than 20% of the total volume.

Flange can provide strong connection.

Carcass ply provides strong frame.

More efficient and economical than combined pipeline in the long term.

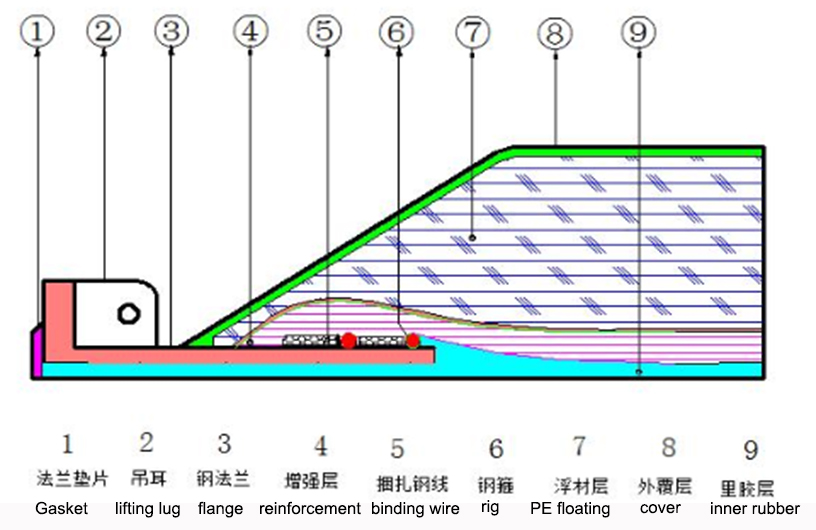

Structure:

Internal rubber layer- high-quality NR, SBR, BR

Inner rubber layer thickness: 15-45mm

Floating layer: PE

Reinforcement layer-------strong tire cord and Floating material layer

External rubber layer--SBR and CR blend

Length:usually 5.8m or 11.8m or at customer's request

Features:

1. Good wear resistance of the inner layer.

2. Colored indicator in the inner layer.

3. Outer cover with excellent abrasion resistance and UV protection

4. Single foam flotation casing to prevent water absorption.

5. The hose emergence above water is not less than 20% of the total volume.

6. Flang design according to customer's requirement.

7. Bending angle : 0°-45° ( Maximum: 90° in short time )

8. The hose has two sides,so can take turns using it.

9. Easy to install, of good adhesion, long service life.

Floating hose Section:

Our advantage:

First, become the preferred solution supplier

Investigate and fully understand the market we choose

Work with clients to build long-term, mutually beneficial partnerships

Provide leading solutions with superior service and quality

Fulfill our commitments and obligations

Second, a fully sustainable fluid handling solution

1. Design and manufacture a simulation system for fluid delivery on site, Help users to accurately understand hose life

2. Use OCRA FLEX software to help users determine hose fluid The best solution for the system

3, using 3D design software to accurately calculate product data for customers Provide reliable products that match theoretical data

Inspection and Testing:

Online

Online 008613393047135

008613393047135

+86 13393047135

+86 13393047135